Grade List

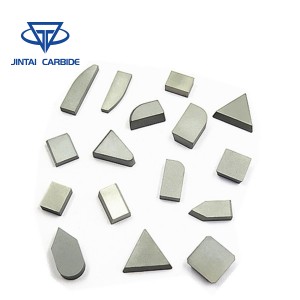

Zhuzhou Jintai Cemented manufactures 2000 different varieties of standard tips conforming to ISO (International Standard), BSS (British Standard), SMS (Swedish Standard) and DIN (German Standard). Zhuzhou Jintai Cemented has developed its Sintered Metal Cutting Grades conforming to ISO standards.

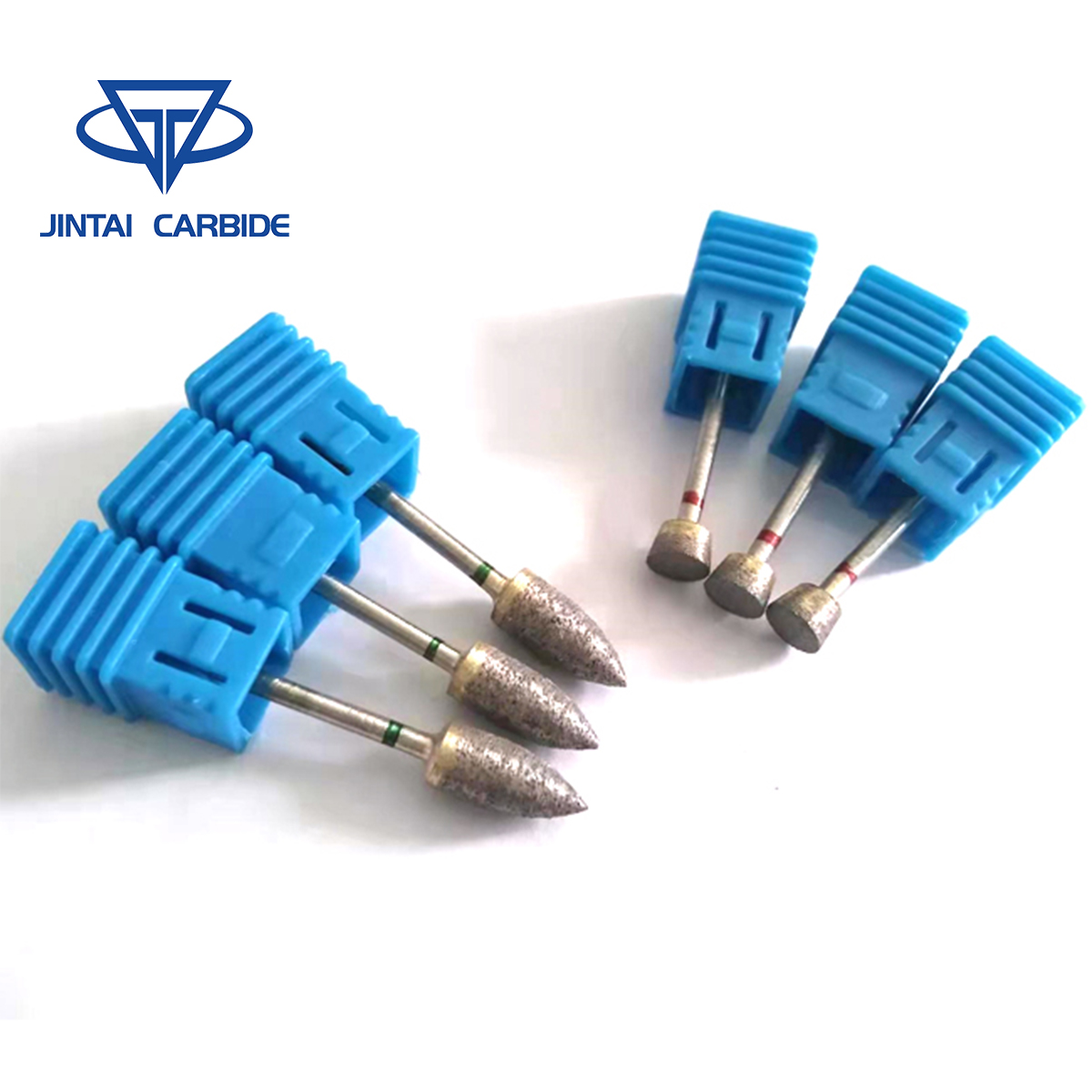

Other than standard tips, Zhuzhou Jintai Cemented continuously tries to develop custom-built special tips for various industries like Automobile, Engineering, Shoe Accessories, Textile, Sugar, etc. Some of the prominent products developed successfully are Blanks for Rotary Burrs, Tips for form tools, flats for knives, Scarfer tools, tips for grooving tools, rods for boring tools, slitting cutter blanks, etc.

Features

1. 100% virgin raw material of WC+CO

2. Wholesale price and High stable quality

3. ISO standard

4. OEM & ODM Service.

5. Application: Turning, milling, threading and parting etc. For finishing, semi-finishing, light roughing and roughing steel, casting steel, alloy steel, cast iron, stainless steel and so on.

6. Outstanding characteristic: good cutting quality ,higher wearing resistance and longer use lifetime.

7. Customized type: we can produce the carbide blade as customer's drawing,size and requirement.

Grade List

| Grade | ISO Code | Physical Mechanical Properties (≥) | Application | ||

| Density g/cm3 |

Hardness(HRA) | T.R.S N/mm2 |

|||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Suitable for precision machining of cast iron and non-ferrous metals. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Suitable for precision machining and semi-finishing of cast iron and non-ferrous metals, as well as for processing of manganese steel and quenched steel. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Suitable for semi-finishing and rough machining of cast iron and light alloys, and can also be used for rough machining of cast iron and low alloy steel. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Suitable for inlaying rotary impact rock drilling and rotary impact rock drilling bits. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Suitable for inlaying chisel-shaped or conical teeth bits for heavy-duty rock drilling machines to tackle hard rock formations. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Suitable for tensile testing of steel bars and steel pipes under high compression ratios. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Suitable for making stamping dies. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Suitable for making cold stamping and cold pressing dies for industries such as standard parts, bearings, tools, etc. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Suitable for precision machining and semi-finishing of stainless steel and general alloy steel. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Suitable for semi-finishing of stainless steel and low alloy steel. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Suitable for precision machining of iron-based, nickel-based high-temperature alloys, and high-strength steel. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Suitable for heavy-duty cutting of steel and cast iron. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Suitable for precision machining and semi-finishing of steel and cast iron. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Suitable for precision machining and semi-finishing of steel and cast iron, with moderate feed rate. YS25 is specially designed for milling operations on steel and cast iron. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Suitable for heavy-duty cutting tools, providing excellent results in rough turning of castings and various steel forgings. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Suitable for inlaying rotary impact rock drilling bits and drilling in hard and relatively hard rock formations. |

Order Process

Production Process

Packaging